- Finance & Trade Centre, Block-D,

Main Shahrah-e-Faisal, Karachi – 75350. - +92 (213) 564-0823

info@apcl.com.pk

Silver Lake Partners FZE (SLP) is setting up 3 MTPA Iron Ore Beneficiation and 1.8 MTPA Iron Ore Pelletization Plant (in first phase) for manufacturing Iron Ore Pellets (IOPs) through its subsidiary Messrs Alhadeed Pelletization Company Limited (APCL).

In this regard, relevant technical studies & tests are being conducted by Allmineral, a leading world-renowned German mineral consultancy firm.

APCL has a baseline requirement of around 1.2 million tons per annum (MTPA) pellet feed for its Pelletization Plant. In order to fulfill this requirement, Iron Ore Beneficiation requires around 1.8 – 2 MTPA crude ore.

The Project would be allotted 50 acres land for development of the plants

Iron ore deposits are present in Pakistan at various locations. Extensive high-quality reserves of iron ore are found in Pachinkoh and Chigendik towns of Nok Kundi area in Balochistan, Kalabagh region in Western Punjab, Chiniot in Central Punjab and Chitral in northern KPK. In Sindh, iron ore is found near Thatta, Sehwan and Nagarparkar. Low quality reserves are also available in Hazara, KPK

Total reserves/ deposits of iron ore in Pakistan amount to 1,427 million tons. APCL is in the process of entering into contractual arrangements with various domestic iron ore exporters.

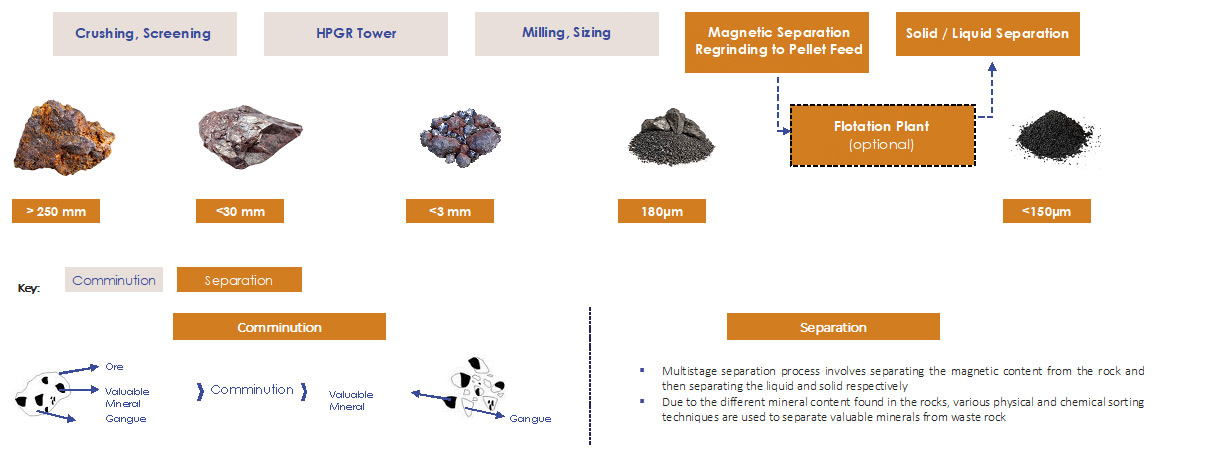

Crude ore from the mines is passed through multistage comminution and separation process to extract the right size of iron content

The process flow starts where the crude ore is crushed and screened at different levels. The size of the crude ore is periodically reduced from 250mm to 75mm, then to 30mm and then finally below 30mm Particle Size Distribution (PSD) are passed on to next stage.

In this section, PSD is further reduced with the help of High-Pressure Grinding Roll (HPGR). The feed is passed through crushing zone with high pressure to reduce the size of the PSD to below 3mm.

The Mill Circuit feeds the outcome from previous section into a ball mill to further reduce the size to 180μm (micrometer). After further processing, the output is sent for magnetic separation.

This step separates the valuable minerals from the waste rock. Due to the different magnetic characteristics of the minerals a three-step magnetic separation process is used.

Low Intensity Magnetic Separation (LIMS) is a wet drum type separator which separates magnetic minerals of the ores and the non-magnetic portion is passed to second stage.

Nonmagnetic particles of LIMS are further separated in Wet Medium Intensity Magnetic Separation (WMIMS) and the remainder nonmagnetic particles are processed in Wet High Intensity Magnetic Separation (WHIMS).

This area separates the solid and liquid particles. Depending on the PSD, different dewatering (filter) technologies have to be considered. The solid particles are the end products needed for the pellet facilities.

Pakistan is bestowed with abundant natural resources including minerals. Although Pakistan is not known as a major Iron Ore producer, however, a number of iron producing sources are spread throughout the country.

In the absence of an active local buyer, currently all this raw iron ore is being sent to China mostly with minimal value addition.